Why Real Performance Depends More on Execution Than Equipment

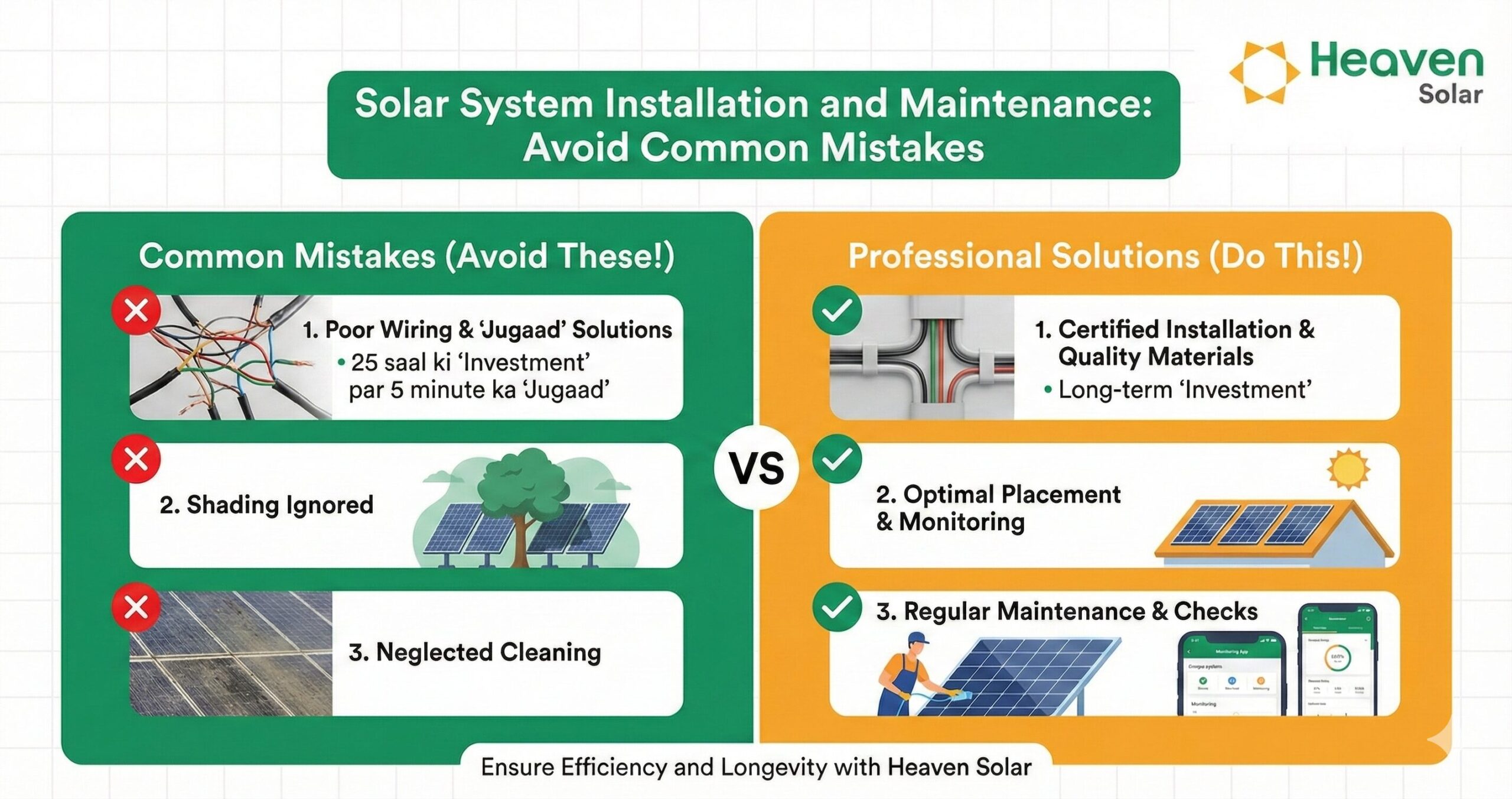

A solar power plant does not perform well just because premium modules or inverters are installed. In real projects, generation depends heavily on how the system is designed, installed, and maintained over time.

Even the best components can underperform if basic engineering principles are ignored during installation. Let us break down the correct approach to solar system installation and long-term maintenance.

1. Solar System Design, The Foundation of Performance

Solar design is not just about capacity calculation. It is about ensuring every module operates under similar electrical and environmental conditions.

Key design principles:

Uniform module selection

All solar modules in a plant should be of the same technology and electrical rating. Mixing different module types like mono and poly or different wattages leads to mismatch losses and reduces overall plant output.

Zero shading philosophy

Even partial shading on a single module can reduce the output of the entire string. Panels must be installed away from water tanks, parapet walls, trees, poles, and nearby buildings. A shading study is mandatory before finalizing layout.

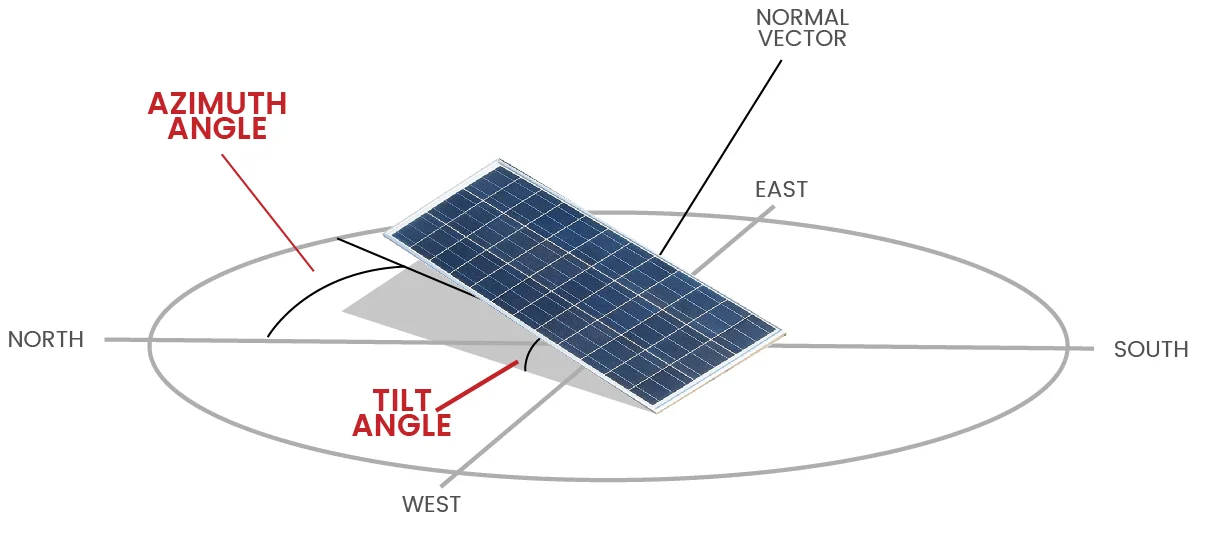

Correct orientation and tilt

In India, modules should face south as a standard practice. Tilt angle should ideally be close to the site latitude for maximum annual generation.

In high-wind zones, lower tilt angles between 5 and 20 degrees are often preferred to reduce wind pressure without compromising much generation.

Safe and accessible layout

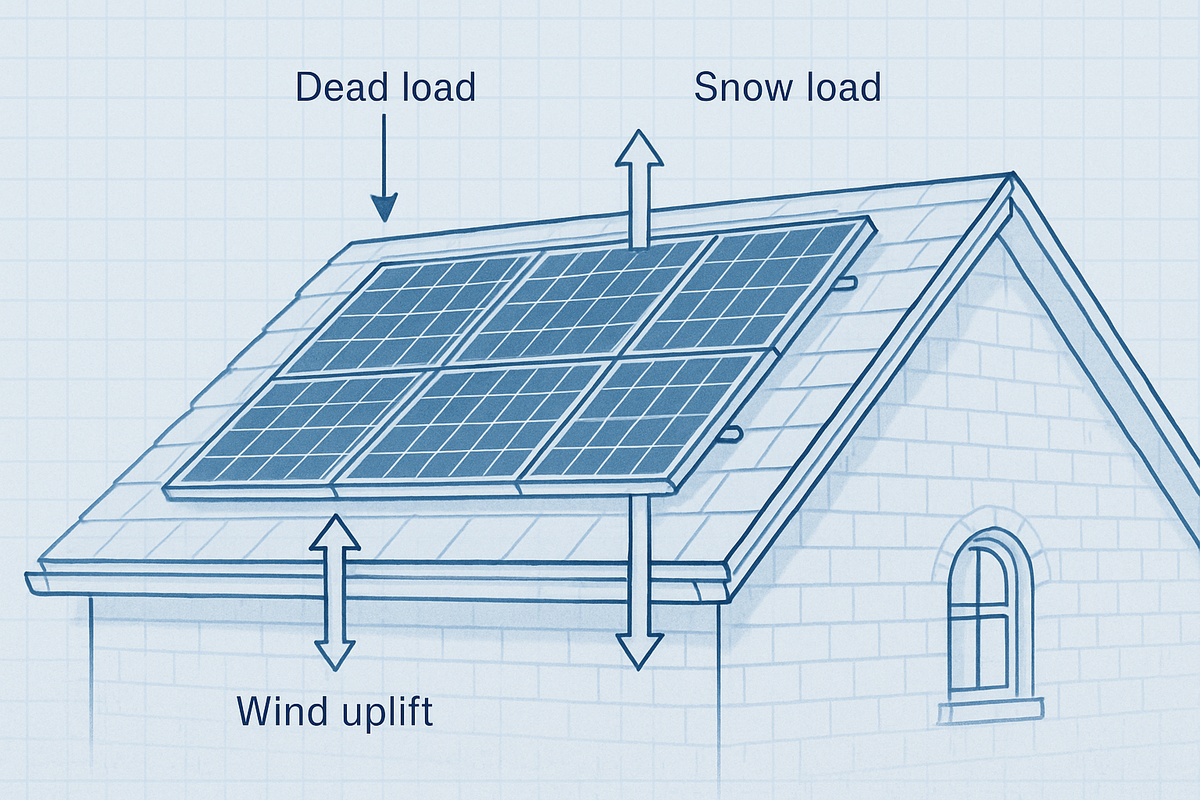

Panels should never be installed at unsafe rooftop edges or cramped locations. Adequate walkways are required for maintenance access. Tight spacing also increases wind uplift risk, which can damage the structure during storms.

2. Installation Quality and Structural Balancing

Solar modules may look rigid, but they are mechanically sensitive. Installation quality directly impacts system life.

Important installation checks:

Proper module spacing and alignment

Modules must be mounted neatly with uniform spacing. Overcrowded installations restrict airflow and increase module temperature, which reduces efficiency.

Roof load capacity

A healthy rooftop should safely support around 25 to 30 kg per square meter including modules and structure. Old or weak roofs need structural assessment before installation.

Correct mounting geometry

Mounting structure legs should be oriented to maximize load distribution. Incorrect leg angles reduce strength and increase the risk of failure under wind loads.

Corrosion resistance

Structures must be free from rust and corrosion. Galvanized or corrosion-resistant materials ensure long-term stability, especially in coastal and industrial areas.

Secure fastening

All clamps and bolts must be properly tightened. Loose fittings can lead to vibration damage or panel loss during storms.

Quality racking matters

A poorly installed structure may not last one monsoon season, while a well-designed racking system easily lasts 20 to 25 years.

3. Inverter Selection and Placement

Inverters are the brain of the solar system and must be treated accordingly.

Best practices:

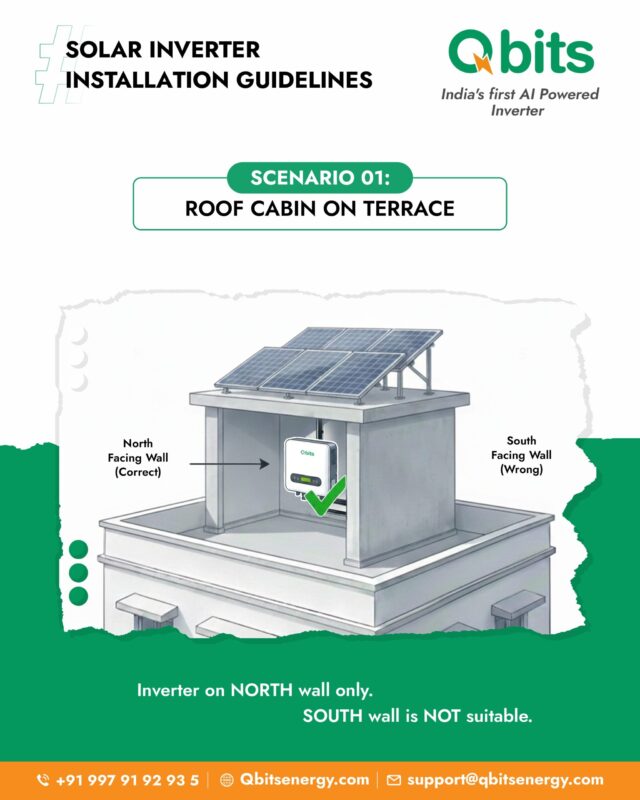

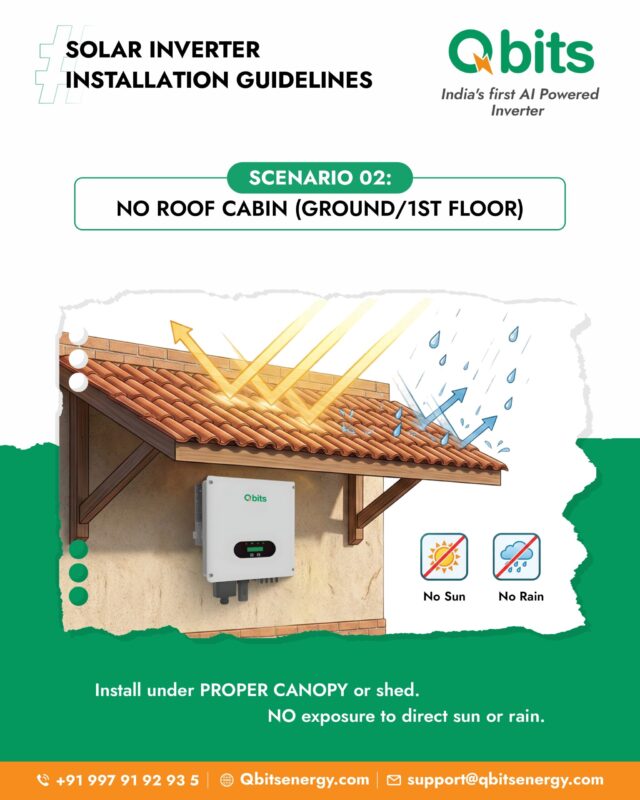

Protection from direct sunlight

Inverters should never be installed under direct sun exposure. Heat reduces inverter efficiency and shortens lifespan. Use natural shade, inverter sheds, or protective covers.

Clear display and monitoring access

The inverter display should be visible and readable. Clear information helps users and technicians quickly identify errors, faults, or performance drops.

4. Wiring and Cable Management

Electrical connections are a common failure point in poorly executed installations.

Essential wiring rules:

Organized cable routing

Cables should be routed through proper paths and secured with clamps. Hanging or loose cables are vulnerable to rodents, water damage, and human movement.

Correct tightness of connections

Loose connections can cause overheating and fire risk. Over-tightening can damage connectors. Balanced tightening is critical.

High-quality insulation

Cable insulation must be intact and UV resistant to prevent electrical faults over time.

Sealed conduits

All conduits must be properly closed to prevent water ingress, insects, or dust accumulation.

Clear labeling

Each cable should be labeled clearly for easy identification during troubleshooting or future expansion.

5. Electrical Protection and Grounding

Protection systems safeguard both equipment and people.

Grounding and lightning protection essentials:

Effective earthing

Proper grounding prevents voltage imbalance and protects the system from electrical faults.

Dedicated lightning protection

PV modules should be connected to a dedicated grounding conductor linked to earth pits. This reduces the risk of damage during lightning events.

6. Maintenance, Sustaining Performance Over Years

A solar plant is not a fit-and-forget system.

Maintenance best practices:

Regular cleaning

Dust and dirt significantly reduce output. Even annual cleaning improves efficiency, while periodic cleaning ensures stable generation.

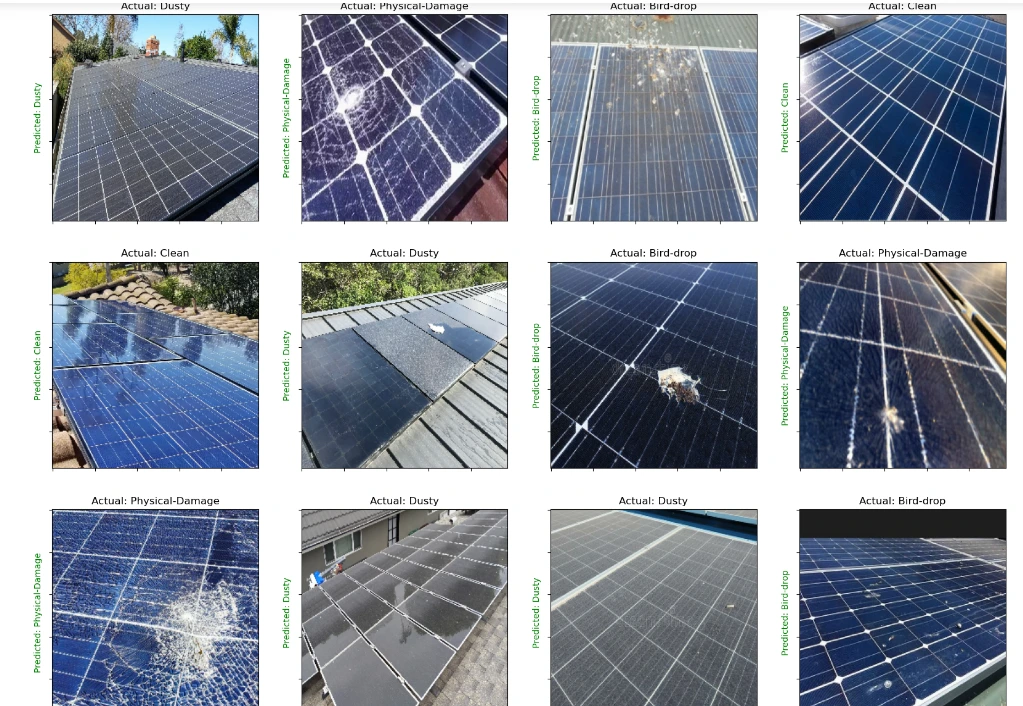

Physical inspection

Modules must be checked for cracks, moisture ingress, delamination, corrosion, or discoloration. Damaged modules should be replaced immediately.

Hotspot monitoring

Hotspots occur due to defective cells or shading. Bypass diodes reduce risk, but persistent hotspots must be addressed to prevent long-term damage.

Safe installation practices

Installers must follow safety protocols like helmets, gloves, harnesses, and insulated tools. Safety is non-negotiable in professional solar installations.

Final Thought

Solar system performance is not defined only by brand or specifications. Design accuracy, installation discipline, and regular maintenance decide how much energy your system will actually deliver over its lifetime.

Choosing experienced professionals ensures that your solar plant is not just installed, but engineered to perform reliably for decades.

At Heaven Solar, we believe solar success is built on engineering integrity, not shortcuts